Ivanhoe’s 100% Off-take of Kipushi’s zinc concentrate, with US$250 million facility supported by Glencore

KIPUSHI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines Executive Co-Chair Robert Friedland and President Marna Cloete, together with Chairman Guy-Robert Lukama Nkunzi and General Manager Placide Nkala Basadilua of Gécamines, the Democratic Republic of Congo’s state-owned mining company, announced today the signing of an off-take and financing term sheet to return the historic Kipushi zinc-copper-lead-germanium mine to production. In addition, Ivanhoe is pleased to provide an update on construction activities for the restart of the ultra-high-grade zinc mine, which is on track for first concentrate in the third quarter of 2024.

Ivanhoe Mines’ President, Marna Cloete commented:

“The off-take and financing milestones are critical deliverables that allow us to return Kipushi to production by the third quarter of next year. Most importantly, these agreements reflect the strength of our partnership with Gécamines and our commitment to the people of the Kipushi community and the Democratic Republic of Congo. The Kipushi underground mine will be the world’s highest-grade major zinc operation, with an average grade of approximately 36% zinc over the first five years of production. We will also endeavour, with our partner Gécamines, to continue exploring Kipushi, including copper-rich and silver-rich zones. Kipushi soon will join Kamoa-Kakula as another tier-one production asset in our portfolio, and mark the next step as we execute our plan to emerge as the world’s newest diversified major mining company.”

Ivanhoe Mines’ Executive Co-Chair, Robert Friedland added:

“In partnership with Gécamines, we are closing in on a monumental achievement to return the great Kipushi Mine to production. When Ivanhoe Mines acquired its interest in Kipushi almost 12 years ago, the mine was flooded and in a dilapidated state. We commend the efforts of the employees of Kipushi Corporation who restored this crown jewel of the DRC. We are proud to see new, state-of-the-art mining equipment, operated by our Congolese employees, underground for the first time in three decades as we begin to open up the Big Zinc deposit, one of the richest mineral endowments anywhere on earth.

Zinc is the fourth most consumed metal in the world, and its supporting role in the energy transition is greatly overlooked as the backbone of clean energy alternatives, including wind turbines and solar panels.”

Gécamines’ Chairman, Guy-Robert Lukama Nkunzi commented:

“We are excited to see this historic mine returning to production with our joint-venture partner, Ivanhoe Mines. This is an important moment for Gécamines, as well as for the local community and the people of the Democratic Republic of Congo. A significant amount of work has got us to this point, which marks another major milestone in this innovative partnership that we have formed and comes with the potential to unlock significant value for the country. Gécamines is expected to attract more investment in the future to bolster in-country transformation and value creation. The Kipushi project, by its unprecedented nature, can form a catalyst for Gécamines to become an important actor in the project’s value chain and for the development of transport infrastructure.”

Watch the video showcasing the signing ceremony for the off-take and financing term sheets, as well as recent project construction highlights: https://vimeo.com/821370084/578ce9e9e8

Signing of the term sheet for off-take and US$250 million financing marks a significant milestone as Kipushi advances to production

Kipushi Corporation SA (KICO), Gécamines SA (Gécamines) and Glencore International AG (Glencore) have signed a tri-partite off-take and financing term sheet.

KICO is 68% owned by Kipushi Holding, a wholly owned subsidiary of Ivanhoe Mines, and the remaining 32% of KICO is owned by Gécamines. As per the terms of the agreement between Kipushi Holding, KICO and Gécamines announced on February 14, 2022, Gécamines will acquire an increasing percentage of the share capital and voting rights in KICO over time.

The off-take is for 100% of Kipushi’s zinc concentrates; between 400,000 and 600,000 dry metric tonnes per annum over a five-year term. The off-take term sheet contains standard, international commercial terms, including payables and treatment charges based on the zinc industry’s annual benchmark. The concentrate produced by Kipushi is expected to contain approximately 55% zinc and low levels of impurities. The buyer will purchase the concentrate at the Kipushi Mine on a free-carrier basis, meaning the buyer will be responsible for arranging freight and shipment to the destination, with such costs reimbursed by KICO.

Signing ceremony at Kipushi. Back (L-R): Ludovic Monga Banza Kabongo, Deputy GM, Gécamines; Olivier Binyingo, SVP Public Affairs DRC, Ivanhoe Mines; Jack Masangu A Mwanza, Deputy GM, Gécamines; Stephane Cormier, Advisor, Gécamines. Front (L-R): Thomas Fogel, Glencore International; Ivano Manini, General Manager, KICO; Louis Watum, Chairman, KICO; Nick Popovic, Glencore International; Marna Cloete, President, Ivanhoe Mines; Guy-Robert Lukama Nkunzi, Chairman, Gécamines; and Placide Nkala Basadilua, GM, Gécamines.

The US$250 million term financing facility will be split into two tranches and drawn down quarterly, subject to conditions precedent. The facility will bear an annual interest rate of the Secured Overnight Financing Rate (SOFR) plus 7% and shall be repaid, following a 24-month grace period from signing, in quarterly instalments over 36 months.

The off-take and financing term sheet is subject to the execution of final, binding agreements, which are expected to be concluded in conjunction with the new Kipushi joint-venture agreement.

Activities to date at Kipushi have been funded by way of a shareholder loan from Kipushi Holding, which totaled US$661 million as at March 31, 2023. The remaining initial capital cost for the Kipushi project in 2023 and 2024 is US$380 million, in line with Ivanhoe’s guidance. The company is also evaluating an interim bank financing facility of up to US$80 million.

(L-R) Didier Kalamba Masengo, Geologist, KICO; Guy-Robert Lukama Nkunzi, Chairman, Gécamines; and Placide Nkala Basadilua, GM, Gécamines taking grade samples of Kipushi’s ultra-high-grade zinc ore using Niton (X-ray fluorescence or XRF) analysis.

Underground mining activities advancing ahead of schedule, in preparation for stoping of the ultra-high-grade Big Zinc deposit to commence in January 2024

In preparation for the start of underground development, early works activities were completed ahead of schedule in Q3 2022. This comprised the refurbishment and supporting of key mining excavations, as well as blasting of the truck-tip turning bays and truck passing bays on the mine’s 1,150-metre level. Explosive storage bays, an underground workshop and a machinery assembly bay were also completed ahead of underground mine development, which commenced in Q4 2022.

In Q1 2023, the underground mining contractor was appointed and commenced the mobilization of its mining equipment to site. The majority of the primary mining fleet is from Epiroc of Stockholm, Sweden, which include six drill rigs, six scooptrams (LHDs) and 13 haul trucks, as well as additional secondary support equipment. Delivery to site of the first batch of mobile mining equipment has taken place.

Mining equipment is slung down to Kipushi’s 1,150-metre level via the P5 shaft. The bulk of the primary and secondary fleet will be delivered by June, with the remainder arriving later in the year as underground development ramps up ahead of the commencement of stoping in early 2024. Stoping is the process of extracting the ore from an underground mine, leaving behind an open space known as a stope.

Underground development is currently taking place to establish access to the Big Zinc orebody. A total of 682 metres of horizontal development was completed in the first quarter of 2023, over 30% more than planned. Perimeter, access and ventilation drives are now under development at several locations between the 1,220-metre and 1,335-metre levels, while decline development continues parallel to the Big Zinc deposit. The decline is currently at 1,340 metres below surface.

The development rate during Q1 2023 averaged 227 metres per month. The rate is expected to increase to 300 metres per month by the end of Q2 2023 and reach more than 400 metres per month by the end of Q4 2023.

Stoping of the ultra-high-grade Big Zinc orebody has been accelerated to commence ahead of schedule, in January 2024. The mining method of the Big Zinc deposit will be transverse sublevel open stoping in a primary and secondary sequence, filled with cemented aggregate fill to maximize the extraction. The underground operation is fully mechanized, cost-effective and designed to enable a quick ramp-up to a steady state of 800,000 tonnes of ore per annum.

The mobilization of equipment by the underground mining contractor. The left-side photo is an Epiroc MB 282 drill rig being slung down shaft P5 and the right-side photo is a recently delivered Epiroc ST14 Scooptram (LHD).

Maintenance crew at the underground workshop, in front of a recently re-assembled Epiroc MB 282 drill rig.

Ore and waste are crushed underground, through a recently installed 1,085-tonne-per-hour primary jaw crusher, and then hoisted to the surface via the P5 shaft. Work on restoring shaft P5’s nameplate hoisting capacity is underway and is expected to be completed in Q4 2023. The hoisting rate is scheduled to increase from the current 101 tonnes per hour to the nameplate 257 tonnes per hour. The crushed ore hoisted to surface will be conveyed via an overland conveyor to the Kipushi concentrator, where it will be stockpiled.

To prepare for concentrator commissioning, approximately six months of run-of-mine ore is planned to be stockpiled on surface to derisk the ramp-up of operations. Medium-to-low-grade ore, as well as mineralized waste from development, is already being stockpiled on surface.

Ndala Ferdinand, Electrician, conducting a routine inspection on electric equipment adjacent to the 1,200-metre conveyor. The conveyor transports crushed medium-to-low-grade ore and mineralized waste from underground development to the P5 shaft for hoisting to surface.

Cadet Kapulula, Drill Rig Operator, operating a bolter machine that is installing rock bolt support at the 1,220-metre level.

Truck loading at the 1,220-metre level. The underground development advancement rate averaged 227 metres per month during the first quarter of 2023.

Concentrator and surface construction advancing ahead of schedule, towards first production in Q3 2024

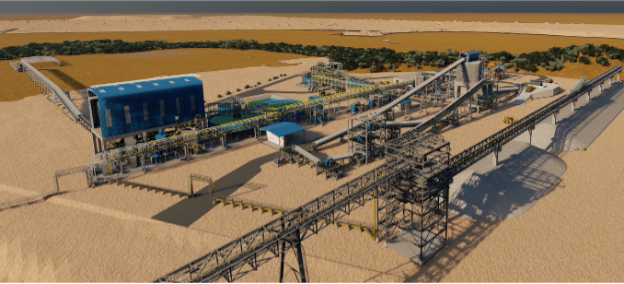

The Kipushi concentrator will have a nameplate capacity of 800,000 tonnes of ore per annum and is anticipated to annually produce 437,000 tonnes of zinc concentrate, at an average grade of 55% zinc. Total life-of-mine production is anticipated to be 10.8 million tonnes of ore at an average head grade of 31.9% zinc over a 14-year mine life (based only on the reserves in the 2022 Feasibility Study), generating 3.3 million tonnes of zinc metal in concentrate.

The concentrator consists of conventional crushing and screening, dense media separation (DMS), ball milling, rougher flotation, tailings and concentrate dewatering and concentrate filtration. The filtered concentrate is bagged in a dedicated bagging plant for dispatch to market. Thickened tailings will be pumped to a new tailings storage facility.

Discarded material from the DMS plant will be mixed with cement in a dedicated cemented-aggregate fill plant and piped back underground where it will be used as a backfill for mined-out stopes.

3D rendering of the Kipushi 800,000 tonnes-per-annum concentrator, scheduled to produce first concentrate in Q3 2024

Since the start of construction activities in late August 2022, overall project progress is tracking marginally ahead of schedule, at 27% complete.

Detailed engineering design for the Kipushi concentrator and associated surface infrastructure is effectively complete. Procurement activities are advancing on schedule and are currently 79% complete. All long and medium-lead-order equipment items have been ordered and are undergoing fabrication. The ball mill, fabricated by CITIC Heavy Industries of Luoyang, China, is undergoing final inspection and is due to be shipped in the coming week. The DMS plant, fabricated by Bond Equipment of Sandton, South Africa, is expected to be complete and shipped to site in the next month. The fabrication of the rougher flotation cells by FLSmidth of Copenhagen, Denmark, is 24% complete and the cells are expected to be shipped in late July.

Surface construction activities are 11% complete, currently tracking ahead of schedule. The bulk of the earthworks and civil works are nearing completion.The structural steel, piping and plate work (SMPP) contractor has been appointed and mobilized to site. Two-thirds of the structural steel requirement has been ordered, with approximately 500 tonnes already fabricated and either en route to or delivered to site. To date, 2,400 cubic meters of concrete have been poured and the first steel erection has recently taken place (see pictures below).

An aerial view, looking southwest, of the civil works under construction at the Kipushi concentrator site (centre picture). Ore will be conveyed from the nearby P5 shaft to a run-of-mine (ROM) stockpile adjacent to the Kipushi concentrator (right of picture).

Concrete foundations of the DMS plant, with the head frame of the P5 shaft in the background. Construction activities are progressing ahead of schedule.

Erection of structural steel for the overland conveyor’s Transfer Tower 3. The conveyors will move ore from the nearby P5 shaft to the ROM stockpile adjacent to the Kipushi concentrator.

Erection of the reinforced concrete walls, and support structure for the DMS feed bin, adjacent to the concentrator ROM stockpile.

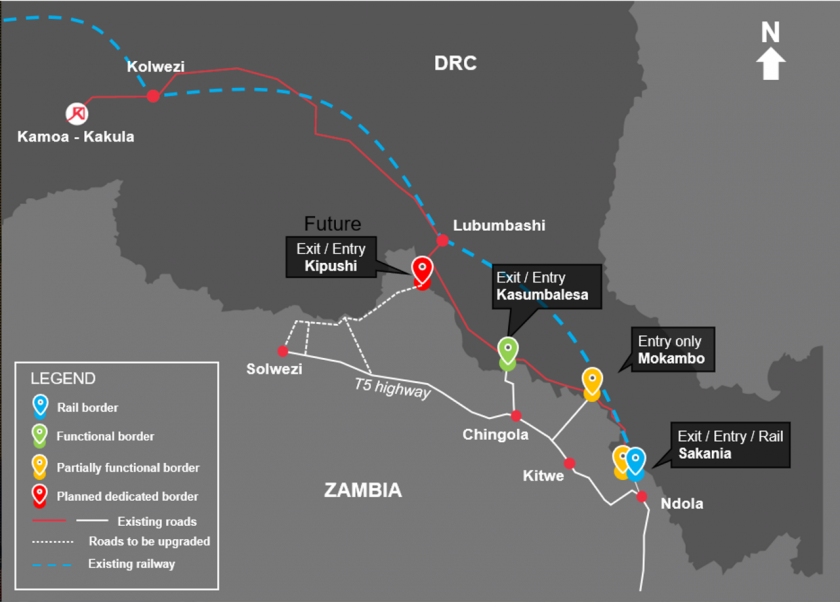

Dedicated Kipushi commercial border crossing to unlock direct access to Zambia

Kasumbalesa and Sakania, in Haut-Katanga, are the two commercial border crossings that currently handle most imports and exports originating from the DRC Copperbelt. They are located 110 kilometres and 230 kilometres by road southeast of Kipushi, respectively. The Kasumbalesa border experienced significant congestion in 2022 and Ivanhoe Mines has been working with the provincial government of Haut-Katanga on a series of initiatives to reduce border congestion and streamline the process of clearing mineral products for export.

One such initiative included a Memorandum of Understanding (MOU), signed in Q3 2022, between the province of Haut-Katanga and Ivanhoe Mines, to study options for a new commercial DRC-Zambia border crossing at the town of Kipushi.

A new commercial DRC-Zambia border crossing at Kipushi will not only benefit the Kipushi Mine but also Kamoa-Kakula as an additional route for exporting concentrate products. In addition, the border crossing will provide socio-economic benefits to the local community of Kipushi and Lubumbashi, the capital of Haut-Katanga province, which is less than 20 kilometres away.

Figure 1. Map of the current and planned commercial DRC-Zambia border infrastructure.

Initial studies have been completed and the various options presented are currently under review by the provincial government of Haut-Katanga and are being discussed with the national authorities in the DRC. Concurrently, a study is underway to upgrade roads for commercial traffic on the Zambian side of the border, connecting the T5 highway to the Kipushi border (See Figure 1). The Zambian government has already commenced upgrades on some sections, with further infrastructure upgrades and all-weather proofing planned to take place over the next 12 to 18 months.

Health and safety at Kipushi

At the end of Q1 2023, the Kipushi Mine reached a total of 1,469,552 work hours free of lost-time injuries and a Total Recordable Injury Frequency Rate (TRIFR) of 1.2 injuries recorded per 1,000,000 hours worked in the first quarter. For comparison, the TRIFR for 2022 was 1.9. It has been more than five months since the last lost-time injury occurred at the project.

Kipushi follows the example of Kamoa-Kakula with a strong focus on local recruitment and progressive workforce training

Approximately 1,480 employees and contractors are currently working on the construction of the Kipushi Project. Of the 536 full-time employees at Kipushi, more than 95% are Congolese and 11% are female. Female employee representation has risen from approximately 7% at the end of 2021.

A plan is underway to ensure that skills and practical experience gained during Kamoa-Kakula’s construction, commissioning and operations are shared with the leadership and operations staff at Kipushi.

Staff from Ivanhoe Mines regularly visit Kipushi and contributes to on-site capacity building, coaching and training, sharing lessons learned and experience gained at Kamoa-Kakula, while key personnel from Kipushi visit Kamoa-Kakula to learn from practical experience. A comprehensive up-skilling training program is also under development for Kipushi and is expected to be rolled out in Q3 2023.

Female staff members at Kipushi celebrating International Women’s Day in March 2023.

![]()